Make Your Products Distinct

Black Diamond Structures is focused on challenging applications in Energy Storage. Contact us to find out how we can help you in building a better battery!

The workhorse of the battery industry. The product and its chemistry have been proven over >135 years. Without them, life in the 21st century would have been very different.

Black Diamond Structures addresses these challenges and enabled our customers to deploy millions of MOLECULAR REBAR®-enabled, advanced batteries into the automotive, storage, traction, and eVehicle applications, globally.

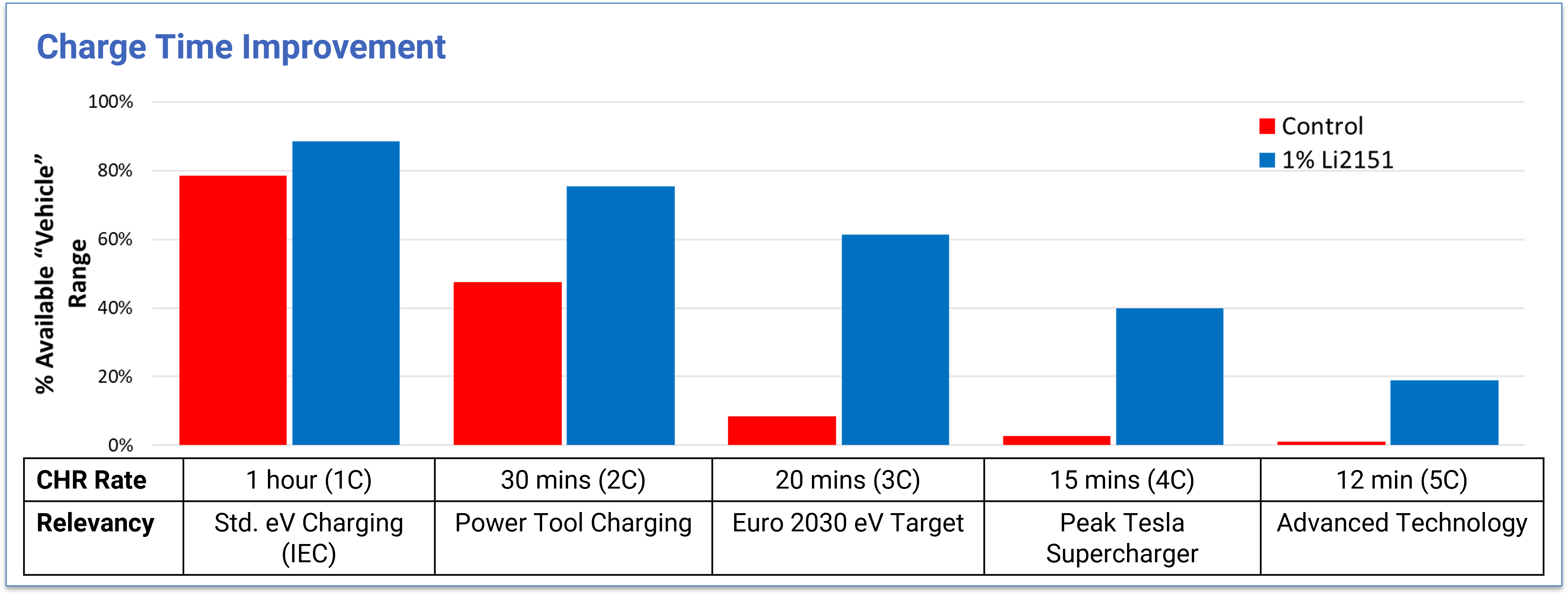

Contemporary technology, advancing at an unprecedented rate, globally. The big breakthrough in Li-ion happened in the 1990s. Today, global demand is outpacing many forecasts, being largely driven by the consumer electronics and electrical vehicle markets.

Black Diamond Structures are in the final stages of commercial validation with several partners who will put MOLECULAR REBAR®-enhanced Li-Ion cells onto the road, into your hand, and into the air over the next few years.

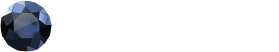

Dramatic MR-based improvements to available vehicle range (capacity, as % of C10) are observed following increasingly high rates of charge

Limitations in charge times has been a key barrier in the adoption of electric vehicles globally. With Molecular Rebar, charge times can be decreased substantially over typical carbon black based formulations.

Impact: 160 miles delivered in 15 mins.

MR permits high charge currents to flow for longer before becoming limited by the battery’s resistance.

This improvement over conventinal formulations opens new doors for battery and charger design.

Our processing and formulation technology results in improved performance from any raw nanomaterial

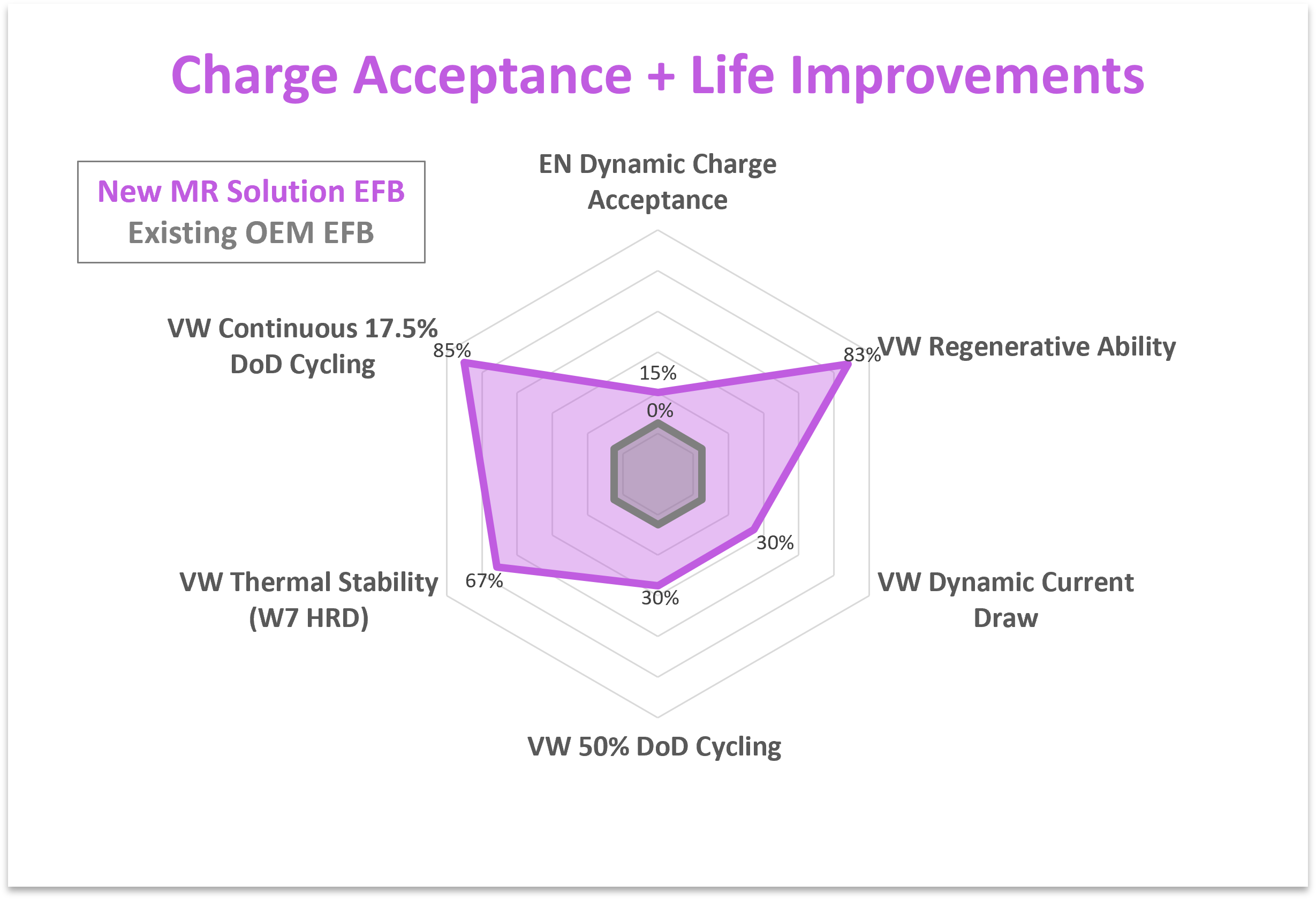

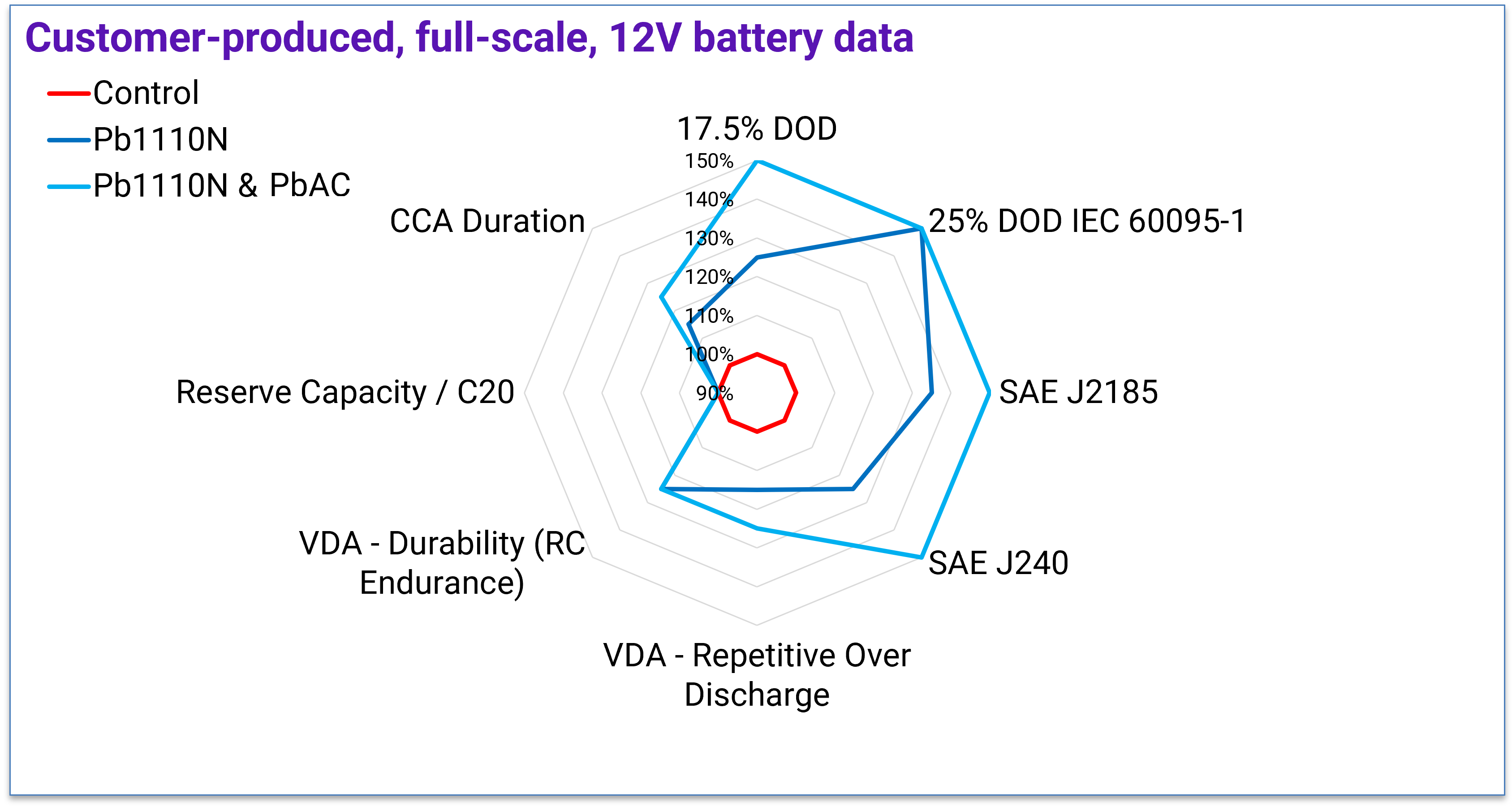

Molecular Rebar brings substantial improvements in many industry relevent tests. These tests are trusted by our customers and have translated well to their field data. With reduced returns and longer life customers are able to save money while providing a superior product.

Our impact in lead acid battery peformance goes beyond our lab. One of our new solutions was graduated from our 2V Lab and validated in an EU 12V build of excellent quality.